Model No.︰MACXG-60

Brand Name︰guang zhou marchi

Country of Origin︰China

Unit Price︰-

Minimum Order︰1 pc

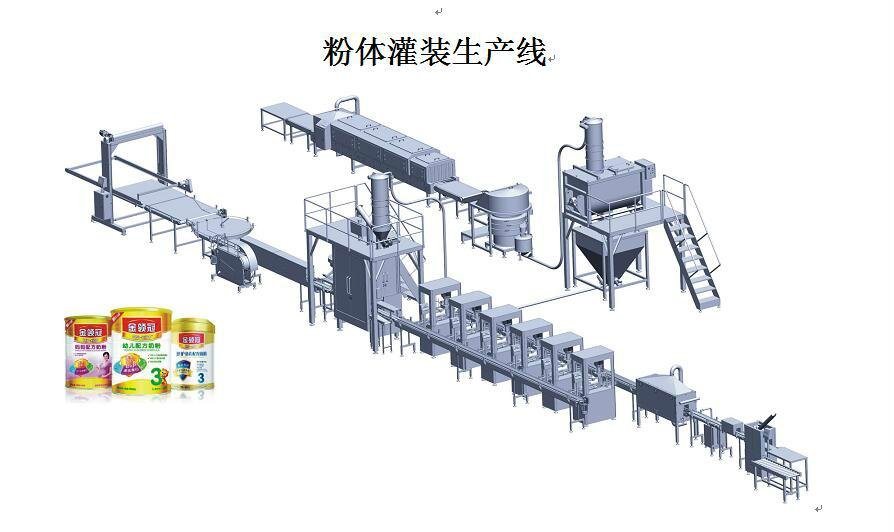

Equipment introduction:

The filling production line is mainly used for filling powder materials. It is suitable for measuring powder and granular materials which are easy to flow or have poor mobility. For example, powdered milk, protein powder, flour, solid beverage, cocoa powder, chicken powder, white granulated sugar, glucose, food additives, feed, medicine raw materials, pesticides, dyes, flavors and fragrances, etc.

Equipment flow:

Outsourcing and debacking → tunnel sterilization transportation → inner package unpacking and feeding → pneumatic conveying → batching mixing → temporary storage → pneumatic conveying → metal detection

Automatic tank unloading → conveying → tank management → tank turning and purging → sterilization → conveying → automatic spoon feeding

Weighing and filling → vacuum filling and nitrogen filling sealing → tank cleaning → laser marking → automatic turning over → plastic cap Capping → finished product collection platform

Equipment details:

Macxg-60 automatic can unloader

Technical parameters:

1. Running speed: ≥ 60 tanks / min (in case of timely supply of empty tanks)

2. Maximum tank stack specification: 1400 * 1300 * 1800mm

3. Power supply: 3P ac208-415v 50 / 60Hz

4. Power: 1.6kw 5. Shape: 4766 * 1954 * 2413mm

6. Function: send the empty cans of one layer to the can management machine, which is used for unloading tinplate and aluminum cans

working principle:

Manually transport the whole tray empty cans to the designated position (stacking mode is the can mouth upward), click the start button, the system will automatically determine the height of empty can tray through photoelectric detection, according to the demand of the buffer belt on the tank, push the one layer of empty can onto the buffer surface plate through the scraper, and then adjust the upper and lower height to connect with the buffer belt of the rear track, and then empty the tank Send it to the buffer belt for use. The buffer belt will continuously send the cans to the can management machine according to the needs of the can management machine. After receiving the reminder, the paperboard between the two layers of empty cans will be removed manually until all empty cans on the whole tray are unloaded, and then the next cycle will be carried out.